Introduction

In the high-stakes world of subsea research, offshore energy, and environmental monitoring, precision, reliability, and adaptability are non-negotiable. For over 25 years, K.U.M. Umwelt- und Meerestechnik Kiel GmbH has been at the forefront of deep-sea engineering—trusted by world-leading scientific institutions, energy operators, and government agencies to deliver robust, mission-ready subsea instrumentation.

Two Systems, One Philosophy: Precision at Any Depth

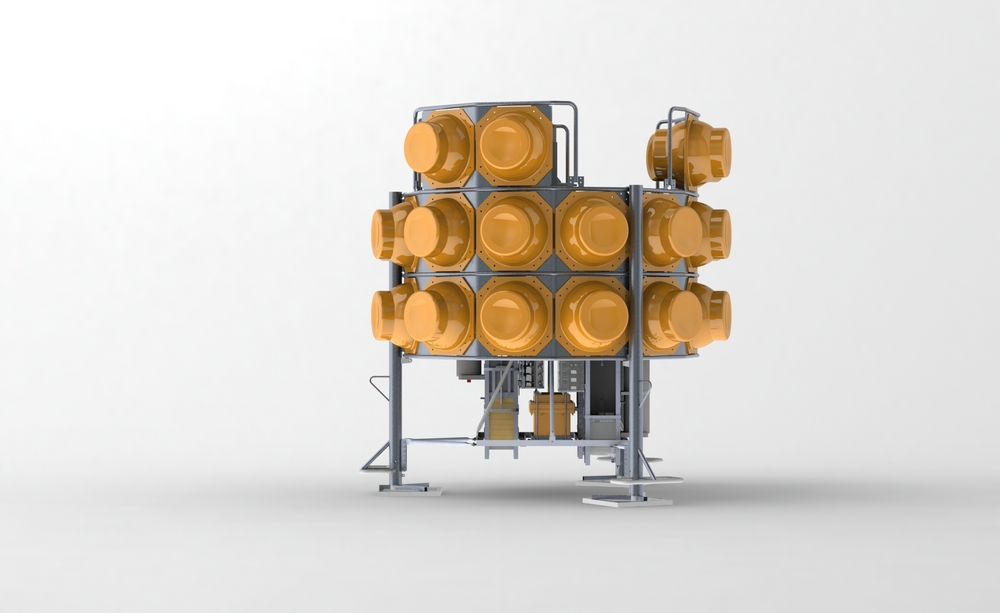

K.U.M. Kiel offers two primary subsea lander models; each built on a modular architecture that supports a broad spectrum of marine missions.

The Standard Lander is constructed on a lightweight yet durable frame and is designed to accommodate interchangeable payloads such as high-resolution cameras, sediment traps, acoustic sensors, and chemical samplers. It is ideally suited for short- to mid-duration scientific or industrial surveys, offering flexibility and ease of deployment.

For more complex and extended operations, the HiCap Lander serves as a high-capacity, multidisciplinary seabed observatory. Engineered for long-duration campaigns, it features enhanced battery capacity, expanded data storage, and the ability to host multiple sensors simultaneously. This makes it particularly valuable for carbon capture and storage (CCS) site monitoring, deep-sea geochemical profiling, and biodiversity assessments.

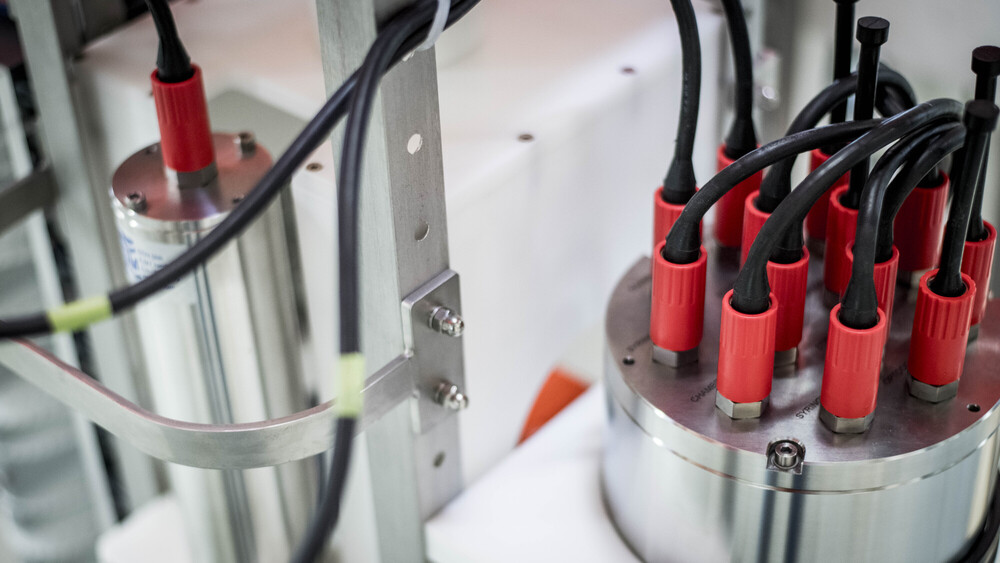

Both systems are fully compatible with K.U.M.’s broader suite of instrumentation, including ocean bottom seismometers (OBS), geophones, and acoustic modems—ensuring seamless integration across mission requirements.

Real-World Application: From Trench to Transition

K.U.M. Kiel’s seabed lander platforms have proven their versatility and reliability across some of the world’s most demanding subsea missions—delivering critical data for scientific discovery, environmental monitoring, and offshore energy development.

One of the most remarkable examples of their performance occurred in the Clarion-Clipperton Zone of the Pacific Ocean. In a groundbreaking study led by Heriot-Watt University, K.U.M.'s HiCap Lander was deployed to investigate microbial ecosystems within deep-sea manganese nodules. The mission uncovered evidence of “dark oxygen” production—a process previously undocumented in oceanic environments—reshaping our understanding of biogeochemical processes on the seafloor. The successful deployment under extreme conditions underscored the platform’s endurance, precision, and scientific value.

Beyond research, K.U.M.’s landers are now integral to a growing range of commercial and environmental subsea applications:

- Carbon Capture & Storage (CCS): Landers are used for gas seepage detection and CO₂ leakage monitoring, providing the high-resolution data required for regulatory compliance and long-term reservoir integrity.

- Infrastructure Monitoring: Deployed near subsea pipelines and offshore platforms, K.U.M.’s landers enable long-term structural and environmental monitoring to enhance integrity and detect anomalies early.

- Oil & Gas Operations: Lander-mounted sensors support passive seismic surveys and well appraisals, delivering essential insights while minimizing environmental disruption.

- Marine Research: From biodiversity studies to deep-sea geochemical sampling, K.U.M.’s systems enable long-term scientific missions that contribute to ocean stewardship and policy.

Across all use cases, K.U.M. landers are not just instruments—they are enablers of insight, discovery, and operational certainty, empowering clients to navigate the seafloor with confidence. Off-the-Shelf Meets Bespoke Engineering

K.U.M. combines the speed of off-the-shelf availability with the depth of fully bespoke engineering. With a robust inventory of proven frames, flotation modules, acoustic releasers, and housings, landers can be rapidly configured for standard deployments. For complex missions, clients benefit from K.U.M.’s full design-build lifecycle—from requirements analysis and 3D modelling to in-house manufacturing, testing, field deployment, and after-sales support. This makes K.U.M. not just an equipment provider, but a true subsea technology partner

Proven Performance, Global Trust

With over 100 successful deployments and a zero-loss track record, K.U.M. has earned the trust of leading research institutions, energy majors, and government agencies worldwide. Built and tested to the highest standards at their facility in Kiel, Germany, K.U.M.'s landers are fully operational from coastal zones to abyssal depths. Backed by a multidisciplinary team of over 45 engineers and scientists, offering global support—from deployment to training and refurbishment—K.U.M. delivers more than equipment; they deliver mission assurance.

Support That Extends Beyond the Seafloor

K.U.M.’s commitment to mission success doesn’t end at deployment. Every lander is backed by a comprehensive after-sales support program, including expert-led installation assistance, mission-specific operator training, refurbishment and repair services, and ongoing parts and inspection support. All systems are built, tested, and maintained at K.U.M.’s advanced facility in Kiel, Germany—supported by a team of over 45 engineers, physicists, and geophysicists dedicated to ensuring peak performance from start to finish.

Shaping the Future of Subsea Observation

Far more than instruments, these landers are platforms for transformation—empowering institutions and industry leaders to overcome technical limits, generate actionable insights, and make informed decisions in the world’s most demanding marine environments.

Whether advancing frontier science or supporting the global energy transition, K.U.M. continues to deliver certainty, one successful deployment at a time.

To collaborate, request a quote, or explore K.U.M.’s latest lander innovations, find out more about our landers or contact the team at kum@kum-kiel.de.